Home » Products » Topcon » Machine control » MC-Max Grader

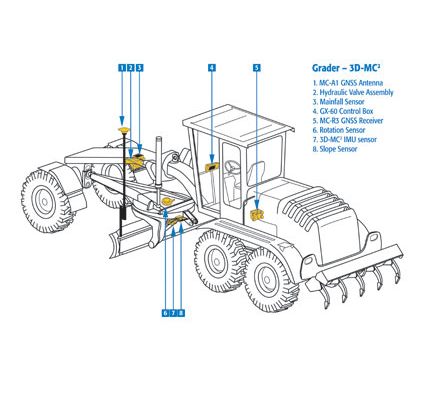

Motor Grader - 3D-MC²

Topcon revolutionized the 3D grading world with the introduction of 3D-MC2 for Dozers. This innovative new technology brought operating speeds and accuracies to crawler dozers that no one had seen before. Now, the same 3D-MC2 System is available for motorgraders.

Features & Benefits:

- Compatible with Topcon 2D & 3D Sensors: Laser, Sonic, LPS, GPS & Millimeter GPS

- Prevents Duck Walking and Undercutting

- Compensates for Rolling of the Mold Board

- Finish Grade at Significantly Higher Speeds & Tighter Tolerances

- Unmatched Productivity You Have to See to Believe

With 3D-MC2 technology slower responding controls are a thing of the past. Operators of all skill levels will increase their grading productivity by more efficiently balancing material and finishing faster. On top of this we’ve added blade tilt compensation and auto disturbance rejection.

Topcon’s 3D-MC2 Motorgrader system is compatible with all of our existing machine control sensors.. If you want to run single or twin antennae GPS, Millimeter GPS with Lazer Zone or a robotic LPS solution, they all work seamlessly with 3D-MC2 Motorgrader. Plus, you can operate in 2D mode with sonic trackers and lasers when the 3D system is not being utilized. (3D-MC2 Motorgrader requires 3D- MC Software Version 10.0.)

Whether buying a new system or upgrading an existing machine, ordering an MC2 system is easy. For new graders all you need is the correct OAF and the 9506-10 hardware kit (MC2 sensor, cable, and mounting bracket).

Higher Productivity. Better Accuracy.

Topcon continues to revolutionize the 3D grading world with the introduction of 3D-MC² for motorgraders. Adding 3D-MC² to a motorgrader allows the control system to immediately sense any changes in the cutting edge position and instantly make corrections providing superior stability and smoothness when finish grading. 3D-MC² works with Topcon’s existing slope sensor to maintain the industries most reliable slope accuracy from flat grades to steep slopes. With the increase in correction speed, operators can breeze through transitions without having to slow down to allow the system to keep up. And Topcon’s 3D-MC² has built in tilt compensation. Whether rolling the blade forward to shave high spots or back to carry a windrow, the system automatically adjusts for the change in position and maintains the correct grade.

How it Works

3D-MC² utilizes Topcon’s GX-60 control box, GPS+ antenna, MCR3 GPS+ receiver and new 3D-MC² sensor and pairs them with our latest advanced software to provide cutting edge position updates up to 100 times per second. The 3D-MC² sensor combines a gyro, compass and inertial sensor to measure the X (front to back), Y (side-to-side) & Z (up & down) position of the cutting edge as well as the roll, pitch, yaw and acceleration of the motorgrader. Result? Unmatched speed, accuracy and flexibility.

Complete System Compatibility

As is the case with most of our technologies Topcon’s 3D-MC² is compatible with all of our existing sensor technologies. No matter if you want to use single or twin antennae GPS, patented Millimeter GPS or a robotic LPS solution, all work hand in hand with 3D-MC². You can even use 3D-MC² in a 2D application with Sonic Tracker and/or a laser when GPS or 3D models are not available. Best of all 3D-MC² is just as easy to install on a new grader as it is to add to those with an existing Topcon GX-60 system. Simply mount the 3D-MC² sensor, update the OAF’s and software and calibrate – you are up and running in no time at all.