Home » Products » Topcon » Machine control » 3D Paver

3D-Paver

Step up from 2D control that relies on benching in stringlines for every lane of asphalt, into GNSS control, where you can go to any location on the site and start paving. Get superior control with greater speed and flexibility at the same time.

Features & Benefits:

- Uses standard Topcon 3D-MC software

- Swap components between other machines

- Eliminate string lines throughout the job

- Increase productivity by 50% and more

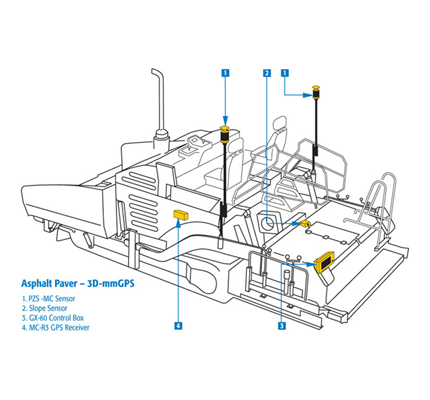

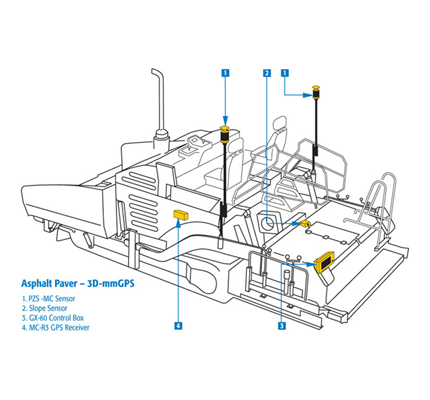

3D Asphalt

Paving 3D-mmGPS incorporates the flexibility of GNSS with the accuracy of a laser Millimeter-accurate control in three dimensions. Using standard Topcon machine control components which can be swapped between machines, the Millimeter GPS system adds a laser transmitter unique to the construction industry that truly augments the GNSS position, to radically improve vertical accuracy. The same job file that controls your grading machines plugs in here too.

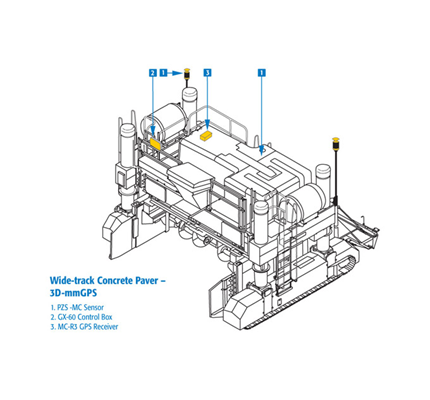

3D Concrete

Topcon’s unique combination of GNSS horizontal positioning and LaserZone™ (mmGPS) for vertical precision provides your wide-track concrete paver with string-less control for the entire job. Move faster, with much less set-up. Integrate easily with the rest of the job phases that are already on 3D control. Only Topcon provides this ease of use, with this reliable control. The same job file that controls your grading machines plugs in here too. Wide-Track Concrete Paver 3D-mmGPS incorporates the flexibility of GNSS with the accuracy of a laser Millimeter-accurate control in three dimensions.

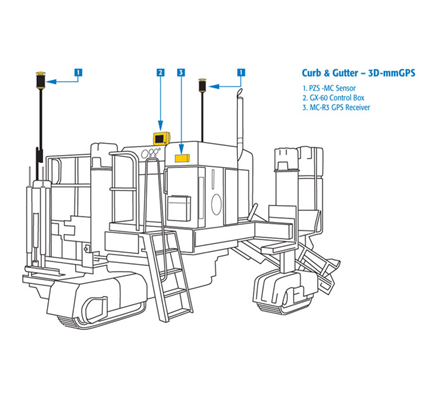

3D Curb and Gutter

The same unique combination of GNSS horizontal positioning and LaserZone™ (mmGPS) for vertical precision provides your Curb and Gutter machine with string-less control for the entire job. Just as with the other 3D paving systems, move faster, with much less set-up. Integrate easily with the rest of the job phases that are already on 3D control. Only Topcon provides this ease of use, with this reliable control.

Standard 3DMC Software

The mmGPS paving systems use the same standard for software. Topcon’s intuitive, easy to use 3DMC software controls the 3D paver with the same functions as other 3D machines. No need to learn a new software or retrain current users, it’s the same software making the transition to 3D paving a breeze!

Swap Components

The 3D paving system uses the same main components as all the other 3D machines. Swap components between the 3D Milling Machine, 3D Grader, 3D Dozer and any other 3D Topcon system. This feature gives the user the flexibility needed to complete a project from start to finish using the same equipment in all phases.

Eliminate Stringlines

As if the ease of use and swappable components weren’t enough, perhaps the biggest sought after feature of 3D paving is the eleimination of stringlines! This direcly affects setup and maintance time on a jobsite which will in turn affect the users bottom line. No need to spend countless hours replacing and adjusting stringlines, they are gone!

Increase Productivity

By eliminating string lines and the time required to setup and maintain them, combined with the ability to use multiple mmGPS transmitters to cover the entire project, productivity increases without question. Jobs can be completed more efficiently, more accurately, more integrated and all with less work making mmGPS a good solution for all your 3D paving needs!

mmGPS Paving

At the heart of Millimeter GPSTM is Topcon’s Lazer ZoneTM technology. This revolutionary technology brings together the simplicity of a rotating laser, the accuracy of a robotic total station, and the flexibility and multiple user capabilities of GPS into one complete jobsite solution! Topcon combines this revolutionary new transmitter with the PZS-MC receiver and Topcon’s GX-60 Control Box and slope sensor to create a system that’s changing the face of paver automation.

Knowing where the paver is located within the digital site plan, and knowing the grade required at that exact position, the control box sends correction signals to the screed to precisely maintain mat thickness and slope for that position on the site. And mmGPS is fast, continuously updating position and grade information so you work as fast as you want.